A new type of coating with the highest known combination of strength, ductility and toughness

immc | Louvain-la-Neuve

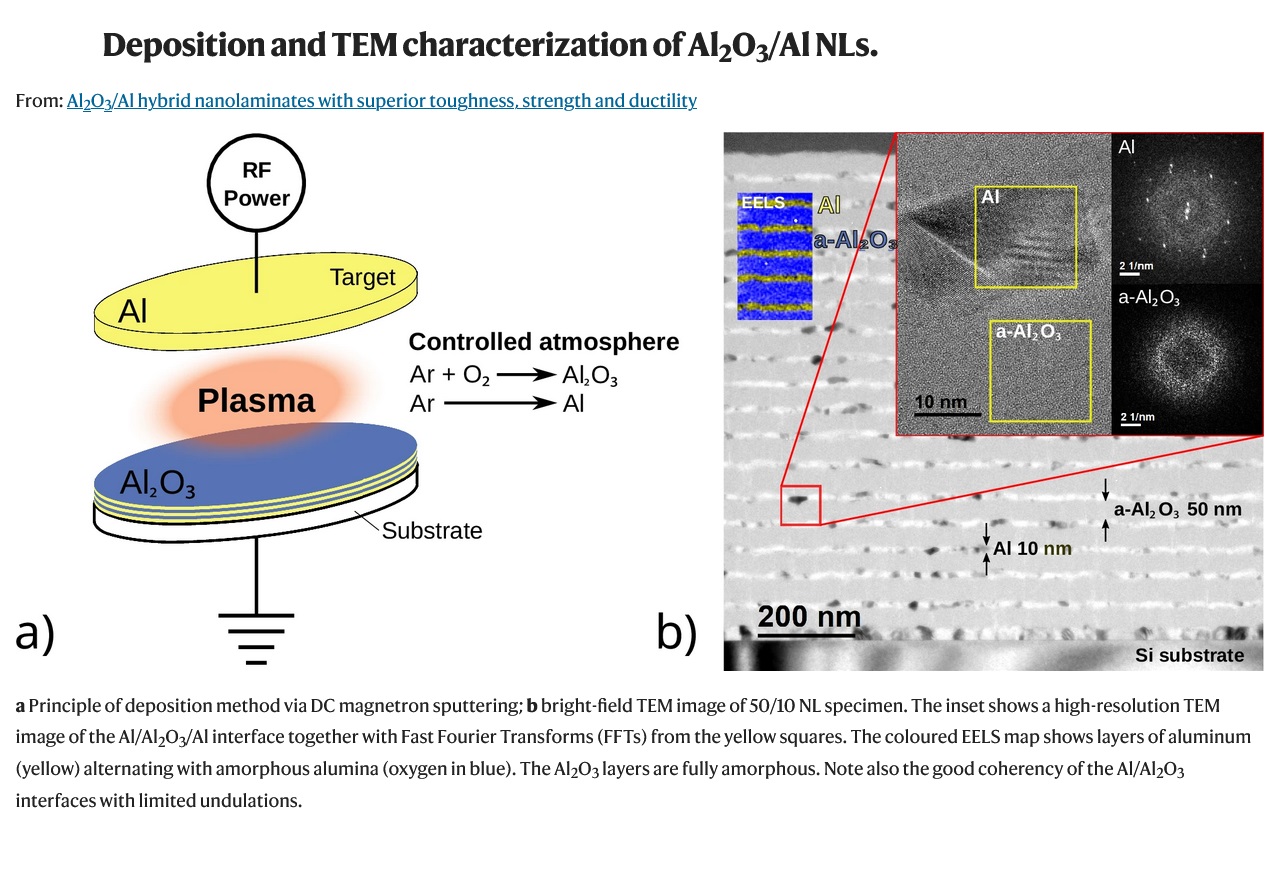

A team from UCLouvain and the WEL Research Institute, in collaboration with the universities of Namur and Antwerpen, have developed a new type of coating with exceptional mechanical properties: a nanolaminate that alternates thin layers of amorphous alumina Al2O3, typically 100nm thick, with even thinner layers of aluminium.

The invention of this material, produced by physical deposition, is based on the principle that amorphous Al2O3 is ductile at a thickness of about 100nm or less.

To obtain a thicker useful coating, it was therefore necessary to stack such very thin layers using the appropriate adhesive. This adhesive is provided by aluminium, giving very strong interfaces with the alumina, while also providing extra energy dissipation during deformation and the ability to stop cracks nucleating in the Al2O3.

The result is a thin coating (thinner than a micrometre) with the highest known combination of strength, measuring the hardness of the material, ductility, measuring the capacity to deform without breaking, and toughness, measuring the ability not to crack in the presence of defects. In addition, this material benefits from Al2O3 excellent corrosion resistance.

The major challenge of this research was to determine precisely the intrinsic properties of this coating and of the independent layers, and then to link them to the physical mechanisms conditioning these excellent properties. To do this, the team used UCLouvain's patented nanomechanical test-on-a-chip approach based on microelectronic manufacturing methods, tensile testing and characterisation using a transmission electron microscope, nanoindentation and finite element modelling. Many applications are envisaged, particularly in technologies involving harsh environments combining corrosion, erosion, wear and mechanical shocks.

This study is published in the journal Nature Communication

Paul Baral, Sahar Jaddi, Hui Wang, Andrey Orekhov, Nicolas Gauquelin, Alireza Bagherpour, Frederik Van Loock, Michaël Coulombier, Audrey Favache, Morgan Rusinowicz, Johan Verbeeck, Stéphane Lucas, Jean-Pierre Raskin, Hosni Idrissi, and Thomas Pardoen Nature Communication (2025) 16:1355

doi.org/10.1038/s41467-025-56512-7

Deposition and TEM characterization of Al2O3_Al NLs