Multiscale models for plasticity and creep in polycrystalline aggregates

Understanding mechanical properties of metallic alloys, such as strength, toughness and ductility, requires proper modeling of how plastic deformation is achieved within individual “grains” forming the polycrystalline microstructure. At the micron scale - thus inside the crystal lattice - micromechanics of metals is governed by the competition of dislocation glide, twinning and phase transformation. All such processes imply significant local anisotropy, which in turn gives rise to highly heterogeneous microscopic deformation patterns as well as large internal stresses

By addressing fundamental questions about microstructure evolution in plastically deforming, single- and multiphase aggregates, we aim at an improved prediction of the mechanical behavior of advanced metallic alloys. The main research axes are:

- The development of advanced single-crystal constitutive laws e.g. that are implemented as numerically efficient user-defined material laws in finite element codes and are assessed thoroughly based on experimental observations at various length scales: lattice strains (neutron diffraction), lattice curvature and twins (ebsd), texture (X-rays), anisotropy and hardening (mechanical tests).

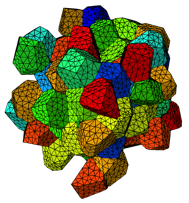

- The definition of statistically representative, polycrystalline model microstructures and their reproduction as conforming, periodic and selectively refined finite element meshes in 2D and 3D.

- he formulation of simplified laws about the interaction of adjacent grains and their use in real-scale simulations of forming processes.